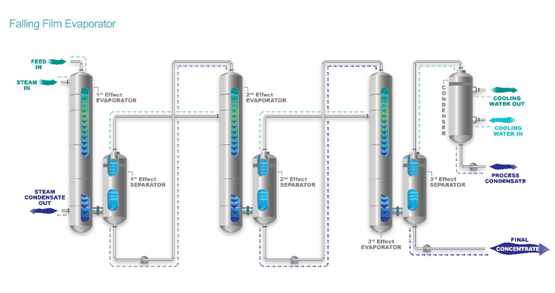

The material liquid to be concentrated is pumped into the top of the heating tubes and flows downward along their walls as liquid film. In this process, the liquid film inside the tubes begins to boil and partially evaporate being heated from outside the tubes. The remaining liquid and vapor are further removed in subsequent separating machines. Reasonably determined material liquid flow prevents bottom section of tubes from getting excessively dry while ensuring optimal thickness of liquid film so that best heat exchange effect and minimum power consumption is achieved. Falling film evaporator is applicable to both cyclic evaporation and one-way evaporation processes.

Applications

- Capacity of single set can reach 200t/h.

- Suitable for heat sensitive materials.

- Suitable for materials with low concentration, low solid content and low scaling.

Particular Features

- High heat transfer coefficient, small temperature difference, vacuum evaporation.

- Material in the heat exchange tube is in a suitable boiling state to avoid dry wall and scaling caused by violent vaporization.

- No loss of boiling point temperature difference caused by liquid column, with small circulation and low power consumption.