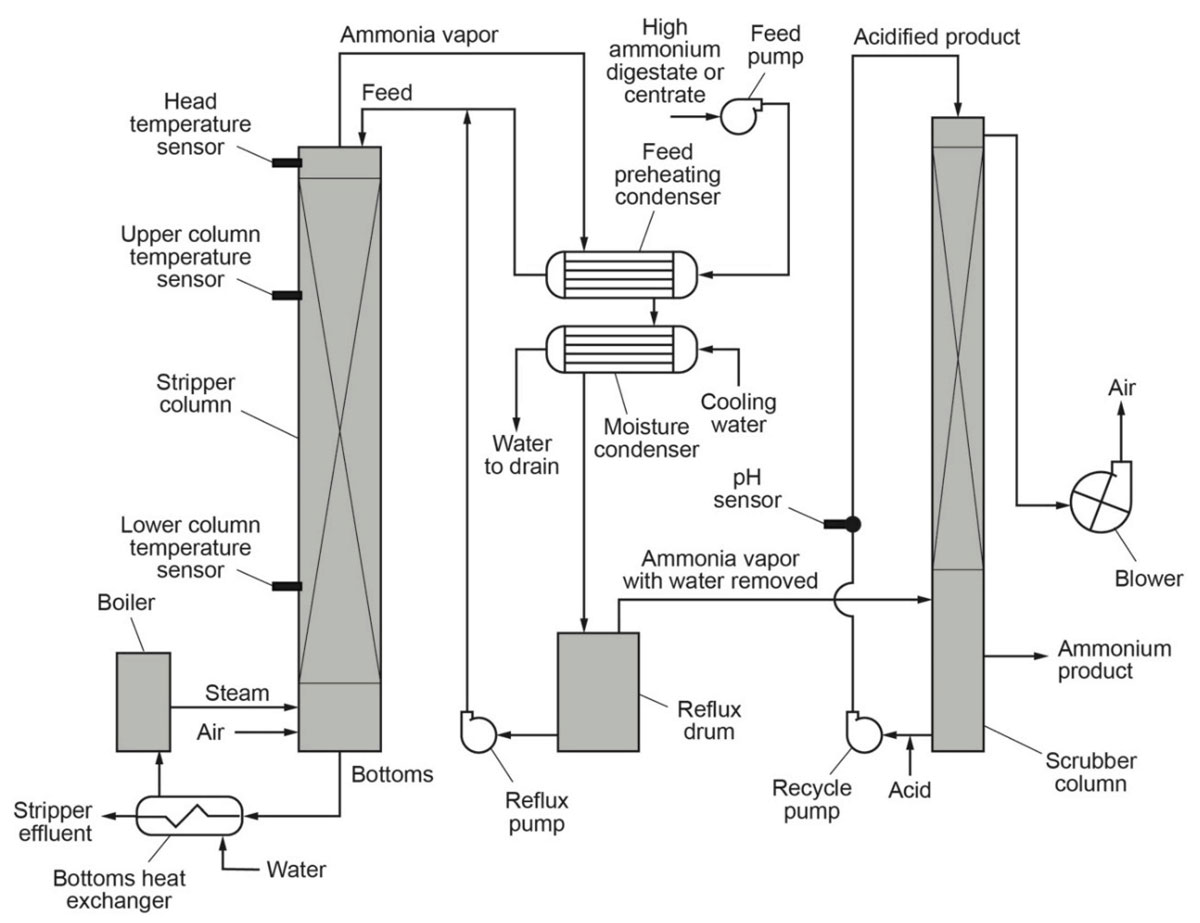

Stripping columns are used to remove volatiles from water such as volatile hydrocarbons (e.g., benzene, toluene and xylene), volatile chlorinated hydrocarbons, to remove low boils such as methanol, ethanol etc from water.

These stripping columns are equipped with either tray or packed column based on the process fluid characteristics and composition.

Sieve Trays

Sieve trays are the least expensive tray option. In sieve trays, vapor flowing up through the tower contacts the liquid by passing through small perforations in the tray floor. Sieve trays rely on vapor velocity to exclude liquid from falling through the perforations in the tray floor. If the vapor velocity is much lower than design, liquid will begin to flow through the perforations rather than into the downcomer. This condition is known as weeping. Where weeping is severe, the equilibrium efficiency will be very low. For this reason, sieve trays have a very small turndown ratio.

Tray Column

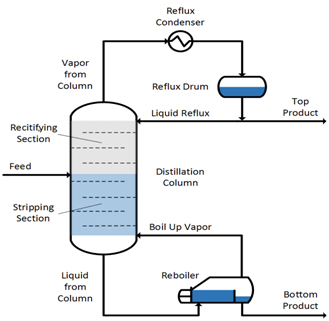

Tray column are separation devices used in process plants, most often in distillation towers or stripper column. The tray column is one the most widely used types of distillation columns. It is also at times referred to as a plate column. The number of trays and stages in the column is designed for the desired purity and difficulty of the separation process.

A tray column that is facing throughput problems may be de-bottlenecked by replacing a section of trays with packings. This is because:

- Packings provide extra inter-facial area for liquid-vapour contact

- Efficiency of separation is increased for the same column height

- Packed columns are shorter than trayed columns